|

CDA: Unrivaled Accuracy

Coaxial Distribution Adjustment System (CDA) Coaxial Distribution Adjustment System (CDA)

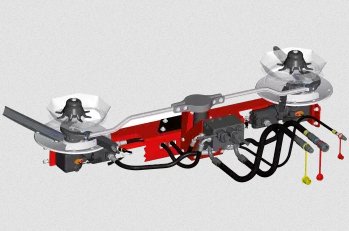

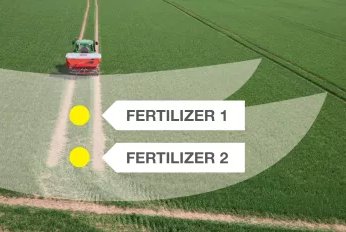

Different fertilizers, variable application rates, multiple working widths – your fertilizer spreader must quickly adapt to different needs. The CDA system, part of every KUHN Axis fertilizer spreader, helps meet these challenges while providing easy adjustments. There are two important features that make the CDA system unique:

1- The pivoting hopper base enables quick adaptation to various fertilizers and working widths by adjusting the drop point of the fertilizer onto the spreading discs.

2- Specially designed metering outlets, close to the center of the discs, allow multiple supply points to the paddles. This helps ensure constant fertilizer flow and an even spread pattern.

You can modify the working width in a few seconds by simply changing the drop point of the fertilizer onto the disc. This is done without any tools by pivoting the base – from the cab via the ISOBUS display. No paddles have to be adjusted and no manual contact with the fertilizer is required.

|

|

Extra-Slow Agitator Extra-Slow Agitator

The agitator regulates the supply, promotes fertilizer flow and helps keep the fertilizer intact. This is because the agitators stop immediately when the metering outlets are closed, protecting the granules from unnecessary agitation. Rotating at only 17 RPM, they handle the granules gently to significantly reduce damage and prevent powder formation.

|

|

More Accuracy with Drop Guide More Accuracy with Drop Guide

To ensure an accurate drop point of the fertilizer on the disc, a brush drop guide follows the fertilizer flow until it is caught by the paddles.

|

|

Reduced Turbulence Reduced Turbulence

Airfin deflectors reduce turbulence generated by the rotating discs to ensure even fertilizer flow.

|

|

Consistent, Uniform Spreading

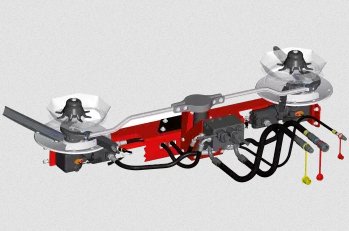

Electronic Mass Flow Control (EMC) System Electronic Mass Flow Control (EMC) System

Electronic Mass Flow Control (EMC) is a unique technology, well-established and proven after years of experience. The EMC system includes hydraulically driven spinner discs, which use proven electromagnetic torque sensors to determine the rate of material falling to each disc separately. This measurement, allows the system to compare the measured rate to the rate set by the operator. If the rate does not match, it automatically compensates by opening or closing the metering gates independently for each side.

|

|

Integrated Weighing System Integrated Weighing System

Included on all AXIS H-EMC-W machines are high-capacity weigh cells. Through the ISOBUS terminal, these weigh cells inform the operator of the quantity of material remaining in the hopper and assist with recording "as applied" nutrient managment maps.

|

|

Hydraulic Disc Drive Hydraulic Disc Drive

The discs, driven by the tractor’s hydraulic system, are independent of the engine. As a result, their spread pattern remains constant and can be adjusted when driving to field points. Spreading with reduced engine speed is possible, which decreases overall fuel consumption.

|

|

Innovative Features to Meet Your Needs

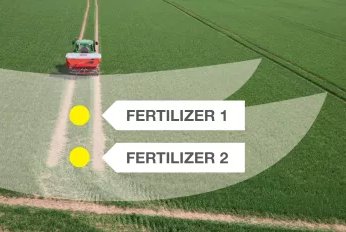

Vari-Spread Pro Vari-Spread Pro

Vari-Spread Pro (Section Control) maintains the proper working width by changing the drop point and the spreading disc speed.

Metering outlets are opened and closed with GPS control. Even in field points Vari-Spread can shut off sections on the left and right sides at the ideal moment. The result is maximum comfort and the highest precision possible.

|

|

Opti-Point Opti-Point

On headlands, most systems typically start spreading at the same point, even though each fertilizer is different. Opti-Point now automatically determines the ideal point to open and close the metering outlets, according to settings made with the GPS system.

Vari-Spread and Opti-Point require the use of a GPS receiver and compatible ISOBUS terminal with the appropriate activations.

|

|

Border Spreading Border Spreading

On Axis H-EMC-W models, border spreading can be engaged on either the left- or right-hand side, via the control terminal.

Two modes of border control are available on either side. Yield mode focuses on feeding the outside rows of crop, while environmental mode virtually eliminates placing any product out side of your set field boundary.

|