Today's HoursTuesday 8:00 am - 5:00 pm

Today's HoursTuesday 8:00 am - 5:00 pm

| Monday | 8:00 am - 5:00 pm |

| Tuesday | 8:00 am - 5:00 pm |

| Wednesday | 8:00 am - 5:00 pm |

| Thursday | 8:00 am - 5:00 pm |

| Friday | 8:00 am - 5:00 pm |

| Saturday | 8:00AM - 12:00PM |

| Sunday | Closed |

Kuhn - MULTI-MASTER L OL 5E

|

The Multi-Master L Series plows are mid-range plows especially well-suited to working behind maneuverable, power-dense utility and row-crop tractors. |

| KUHN Multi-Master L Series plows are available with 4 to 6 bottoms, both on-land and in-furrow to meet the needs of a variety of operations. The “multi” mechanical working width adjustment system allows you to set each furrow up to 20” (50 cm) wide to match your tractor and plowing practices. Traction-bolt (T) or Non-Stop Hydraulic (NSH) reset protects the plow from damage and quickly returns the bottoms to work. Like all KUHN plows, the Multi-Master L is equipped with the exclusive Triplex steel moldboards for unmatched durability in the field. |

|

Heavy-Duty Components to Ensure a Long Machine Life

// Moldboards are made of unequal layer, heat-treated Triplex steel that have an increased working life up to 40% over standard steel and a hard-wearing surface over 1/8” thick. |

|

|

|

The standard hydraulic adjustment changes the furrow width to match a variety of soil types. Exclusive linkages integrated into the frame, protect the adjustment components from damage. |

|

The shock absorber removes the shock of the wheel falling during rollover and also ensures the wheel is in the correct rearward inclined position as the plow is lowered back into work. |

|

A Variety of Options to Meet Your Operation’s Needs

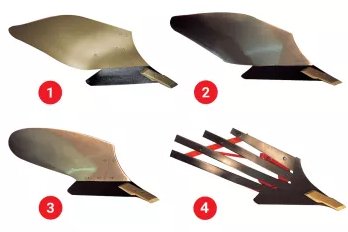

1- The L moldboard is a multi-purpose design that works especially well for in-furrow plowing. Its design cuts a wide furrow bottom to accommodate large tractor tires. The L moldboard will also create varying field finishes depending on the working speed. Slower speeds make more pronounced furrows, while faster speeds provide a flatter field finish. 2- H4 Moldboard: The H4, helicoidal, Scandinavian-type moldboard provides well-formed plowing to a normal depth range of 7-12”. The share is fitted with a reversible/replaceable point that greatly increases the life of the share. Recommended for fall plowing, the H4 moldboard is especially suited for heavy and damp clays. Furrow passes are well defined and trash burial is excellent. 3- N Moldboard: The helico-cylindrical N moldboard plows to a depth of 14”. Designed to be highly versatile, it is cylindrical at front, helicoidal at rear. A low draft ensures a partly broken furrow with excellent trash burial. Recommended for spring plowing, this moldboard is versatile and works well in sandy or clay soils. 4- VP Slatted Moldboard: The VP slatted moldboard composed of independent and interchangeable slats. Reduces pulling power, due to a lower moldboard surface area. Designed for use in extremely sticky muck and clay soils. Not for use in sand or loam soils or in soils with rocks or stones. The multiple slats allow individual replacement from wear. |

|

1- Olympic®: Reversible for maximum efficiency. More pronounced shape at wearing zones on the point for longer life and better protection of the landside. Point is self-sharpening for good ground penetration at all times. 2- Marathon®: Reversible for maximum efficiency and features a step resulting in better landside protection. 3- Super Marathon®: Fitted with a tungsten carbide tip. High wear resistance with four to five times the life of a traditional share point. A sharp working edge is maintained for excellent ground penetration. Excellent for highly abrasive soils without rocks or stones. |

|

1- Traction Bolt (T) Reset. A clean break of the traction bolt, following a force of 5,280 – 8,820 pounds at the plow point, avoids the risk of nuisance shearing. The traction bolt system is economical protection system that avoids the wear associated with shear bolt systems 2- Non-Stop Hydraulic (NSH) Reset. When a field obstacle is met, a rapid breakaway of the plow leg occurs. Once the obstacle passes there is an increase in pressure, bringing the bottom quickly and firmly back into working position. The system also acts as a shock absorber in rocky ground, increasing plow life. 3- Heavy-Duty Plow Leg Articulation and Tie Rod. All force is transmitted in a straight line through a one-piece forged and heat treated tie rod. |

|

The Vari-Master L can be customized to suit any operation with multiple wheel options that provide outstanding depth control and safe, comfortable road transport. |

|

Easy Adjustments

The design of the optional “3D” skimmers features tool-free adjustments for both depth and attack angles. Changing both the depth and attack angle promotes excellent residue flow and burial in all conditions. |

|

The front furrow width is adjusted to its optimum setting according to the tractor linkages and ground conditions. Because of the parallelogram of the two linkages, any adjustment in front furrow width automatically adjusts the angling of the plow, allowing the tractor to always pull in perfect line. Adjustments are quickly carried out by activating a hydraulic cylinder. |

| Download Brochure | Download |

Directions

Directions