Today's HoursTuesday 8:00 am - 5:00 pm

Today's HoursTuesday 8:00 am - 5:00 pm

| Monday | 8:00 am - 5:00 pm |

| Tuesday | 8:00 am - 5:00 pm |

| Wednesday | 8:00 am - 5:00 pm |

| Thursday | 8:00 am - 5:00 pm |

| Friday | 8:00 am - 5:00 pm |

| Saturday | 8:00AM - 12:00PM |

| Sunday | Closed |

Kuhn - HR 4030

| The new HR 1030 Series power harrows carry KUHN’s solid reputation into a new generation with updated features and even better performance. Building on the success of their direct predecessors, the popular HR 1004 D series, the HR 1030 series models have a class-leading driveline rated up to 270 PTO horsepower with the most available rotor speeds in the industry. Newly designed rotors and lubed-for-life gear trough reduce power consumption for high tractor fuel efficiency. An adjustable leveling bar is standard equipment and helps the rear roller create an ideal seedbed in a wide variety of conditions. Other options including quick hitch brackets, stone deflectors, and more, help customize the machine to meet the needs of almost any operation. |

|

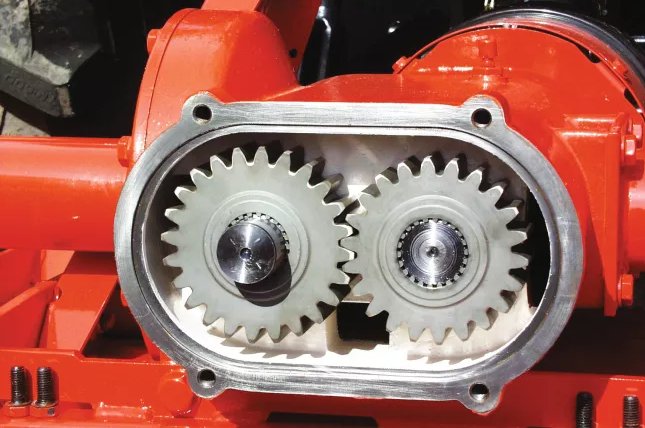

Heavy-Duty Drive Components

HR 1030 series models are compatible with Cat. 2 and 3 hitches. Additionally, Cat. 4N quick hitch adapters are available as a field-installed option. |

|

|

|

Versatile & Reliable"

|

|

The sides of the main gear trough are constructed from 5/16” (8 mm) thick steel for outstanding structural rigidity. Forged-steel, treated gears have a convex shape to transmit all of the drive forces at the center of the upper bearings. These large bearings are preloaded with a spacer, while the lower bearings are held and protected by a one-piece housing that is 28 mm thick. The milled cover and cassette seal keep out contamination that could damage the gears or bearings. The main trough is lubed-for-life with extreme-pressure grease. |

|

Create the Ultimate Seedbed

All HR 1030 series power harrows come standard with blades 12.4” (315 mm) long and 0.63” (16 mm) thick. These blades are designed to reduce power requirements while working up to 9.8” (25 cm) deep for optimal seedbed preparation in a variety of crop applications. Optional DuraKUHN hard-coated blades offer improved durability and lifespan in abrasive soil conditions. Round, flat blade holders are positioned with significant clearance below the trough. Fast-Fit technology promotes quick and easy blade changes, increasing critical uptime in tight tillage windows. |

|

With three different roller options to choose from, the HR 1030 Series power harrows are suited to fit any commercial-sized operation’s needs.

MaxiPacker Rear Roller

|

|

The standard leveling bar mounted behind the rotors helps to smooth out the soil so the roller at the rear of the machine can finish creating the optimal seedbed. The leveling bar’s depth is adjusted mechanically with an easy-to-use crank for raising and lowering. The leveling bar also features three manually-adjusted angles depending on conditions and the seedbed finish desired. The “trailing” position is best suited to shallow depths and higher speeds; the middle position provides the best leveling; and the “forward” position pushes material back toward the rotors for maximum clod breakup. |

|

Mechanical depth control comes standard on all HR 1030 series models and allows the operator to fine-tune the working depth by moving a series of pins. For even greater comfort and ease of use, optional hydraulic depth control allows the operator to stay in the tractor seat when making adjustments. |

| Download Brochure | Download |

Directions

Directions