Today's HoursTuesday 8:00 am - 5:00 pm

Today's HoursTuesday 8:00 am - 5:00 pm

| Monday | 8:00 am - 5:00 pm |

| Tuesday | 8:00 am - 5:00 pm |

| Wednesday | 8:00 am - 5:00 pm |

| Thursday | 8:00 am - 5:00 pm |

| Friday | 8:00 am - 5:00 pm |

| Saturday | 8:00AM - 12:00PM |

| Sunday | Closed |

Kuhn - GF 222 T

|

The KUHN GF 102 Series rotary tedders are designed to meet the needs of small-acreage hay producers who demand the highest quality tedding of forage to ensure even and quick drydown. These tedders have all the features required for high-quality tedding without being hard to operate. These machines feature small-diameter rotors that provide complete turnover and uniform distribution of the hay for unmatched drying speeds. The rotor height and tine angle are easily adjustable to optimize tedding in all crop conditions. Angular wheel adjustment provides oblique tedding at field edges to keep hay from being thrown out of fields or onto fences. |

|

Fast and Uniform Crop Drying and Distribution

For those whose goal is to harvest the highest quality crop – Small rotors are the key to success! Due to their steep pitch angle, small rotors offer many advantages, including a wide angle of attack while turning all of the crop, fast and uniform drying, complete crop inversion, even crop distribution, exceptional ground adaptation, minimum distance to the center of gravity on mounted tedders for reduced lift requirements, and reduced horsepower requirements. |

|

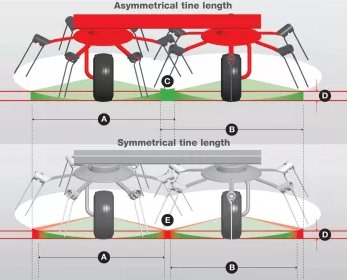

When it comes to tines that actually engage the crop, KUHN leaves nothing to chance: top-quality raw material has been wound into four coils with long tine fingers, giving you exceptional reliability. A defined attachment system to the arms results in an unmatched design life of at least 180,000 cycles. This provides several hundred hours of work before tine replacement is necessary. Asymmetrical tine finger length means both fingers engage the crop equally for a more consistent pickup. The tine guards prevent accumulation of debris around the coils. |

|

The asymmetrical tine length with longer outer fingers has several advantage to bring the machine’s tedding quality to perfection. This allows the outer finger to touch the crop earlier compared to symmetrical tines. It also ensures more complete tedding, along borders and between the rotors, where the tines overlap more in this sensitive area. Contacting the crop sooner means that the actual working width of each rotor is expanded and as a result, the entire machine working width is expanded. (Except GF 222) |

|

Reliable, Low-Maintenance Components

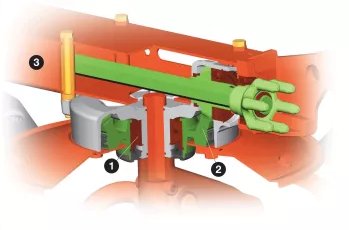

DigiDrive® Coupling System – A Legend in the Making

DigiDrive® Coupling System – A Legend in the MakingWhen a KUHN engineer came up with this drive coupling design, we knew that it would revolutionize the rotary tedder. This patented design made it possible to reliably drive a large number of rotors, yet fold them for unmatched transport ease, all with virtually no maintenance or repairs. Since the DigiDrive coupling’s inception, nearly 20 years have passed and more than 150,000 KUHN tedders are now being used across the world to ted hay with the ultimate reliability. The DigiDrive® contains case-hardened forged steel fingers for improved wear resistance. Synchronization of rotational movement is outstanding both in work and in transport where the components are folded 180° to reduce the machine’s space requirement. The DigiDrive is a highly reliable system requiring very little maintenance – no daily greasing necessary! |

|

With rotors driven by DigiDrive couplings and lubed-for-life rotor housings, the greasing points are limited to a relatively few pivot points allowing you to spend more time in the field and less time greasing. 1- They are supported by large diameter, double-row angular ball bearings. 2- The thoroughly sealed rotor housing prevents lubricant leaks or introduction contaminants. 3- The robust mounting of housings to the edge of the rectangular frame maximizes strength and durability. |

|

Mounted & Trailed Models"

The GF 502 is a fully mounted machine that keeps the rotors close to the tractor for good ground following. The headstock can pivot in the work position allowing the rotors to better adapt to changing terrain or rough conditions. After work is done, activation of the hydraulic valve and lifting the tractor’s 3-point hitch will raise the rotors and automatically center and lock them in transport position. Each wheel on this model can easily be adjusted without tools for accurate tedding along field edges, without losing or wasting precious forage. |

|

The drawbar-style hitch, of the GF 222 T and 502 THA tedders, allows for simple and easy attachment compared to mounted and semi-mounted models. When folding into the transport position, the tines on the GF 502 THA, automatically raise off of the ground for more clearance with the road. When unfolding into the working position, the tines will reset to the working height the operator had previously set. |

| Download Brochure | Download |